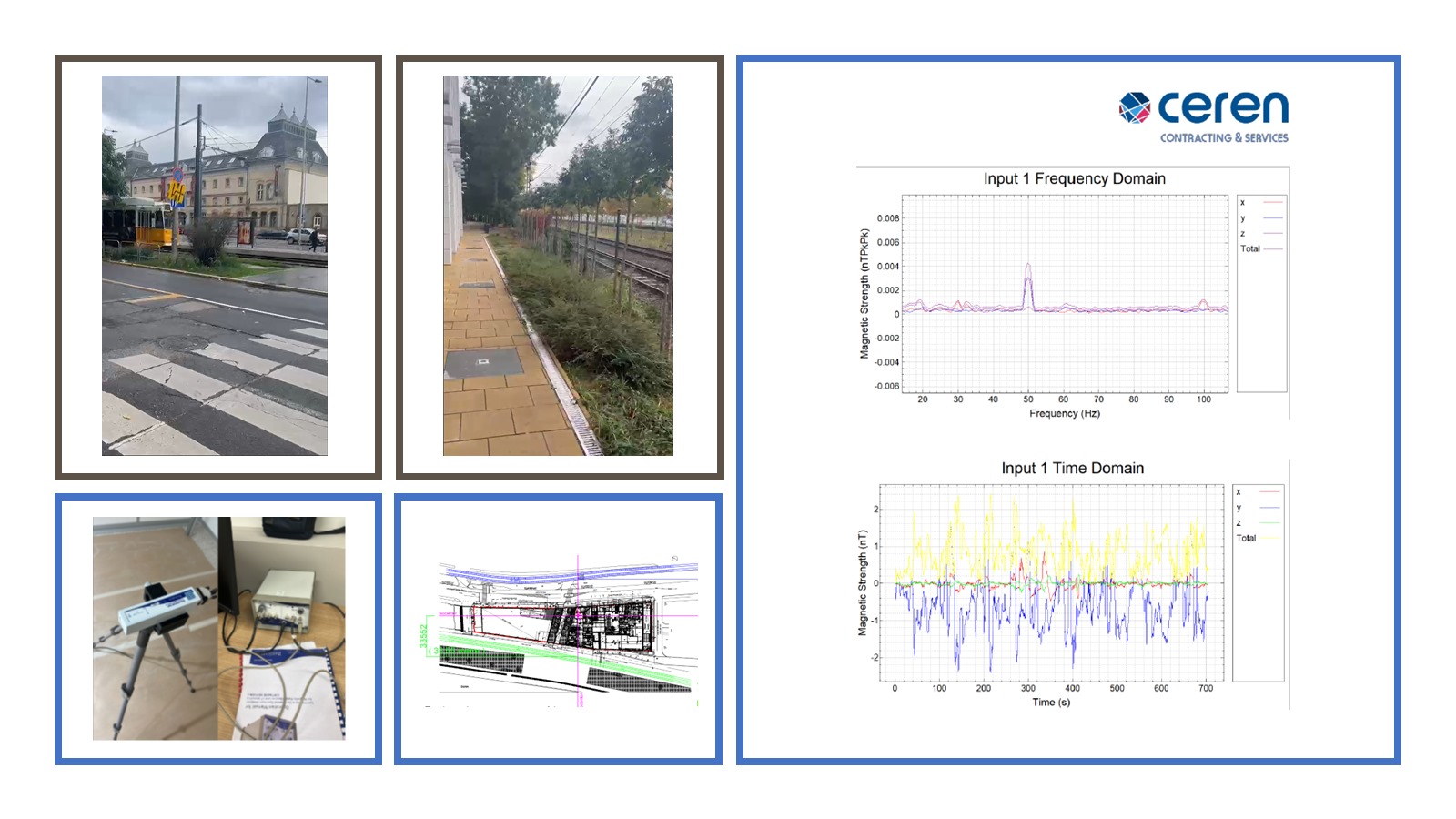

Bo and vibration test:

We perform B0 and vibration test including a report as MRI equipments is very sensitive to environmental vibrations. Structural vibrations can be caused by a number of sources, such as elevators, motors, pumps, and vehicles passing near the building.

Prior to choosing a new MRI location, it is therefore advised to perform vibration testing. Each manufacturer will provide siting criteria for maximum allowed vibrations at various frequencies.

In many cases, the solutions are relatively simple. For example, it may be possible to relocate nearby offending mechanical equipment or install vibration isolation pads under the machinery or the MRI system itself. An even more expensive solution involves isolating the concrete slab on which the magnet rests. In rare cases an alternative site for the MRI will need to be considered.

Transport & Rigging:

We arrange and supervise the “last mile” transport, where we provide custom solutions for both vertical and horizontal transport including cranes and platforms where needed. Our standard MRI rigging deliveries are usually completed within 3-5 hours based on the system and site complexity required for the MRI rigging. We also have MRI rigging wheels for sale for MRI systems.